Fixing a Paper Cutter

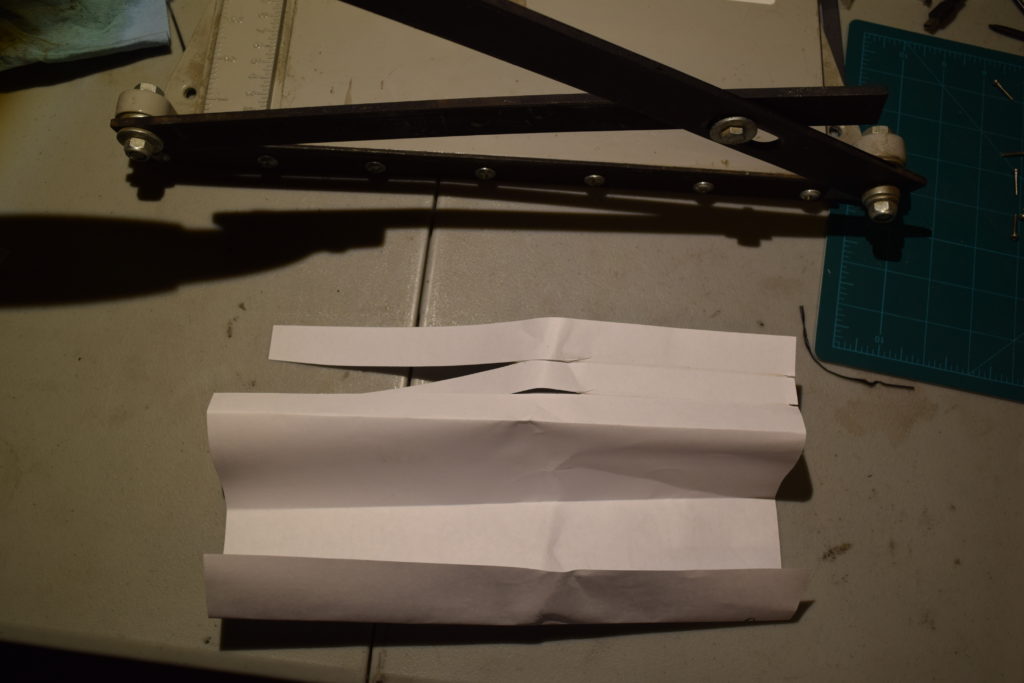

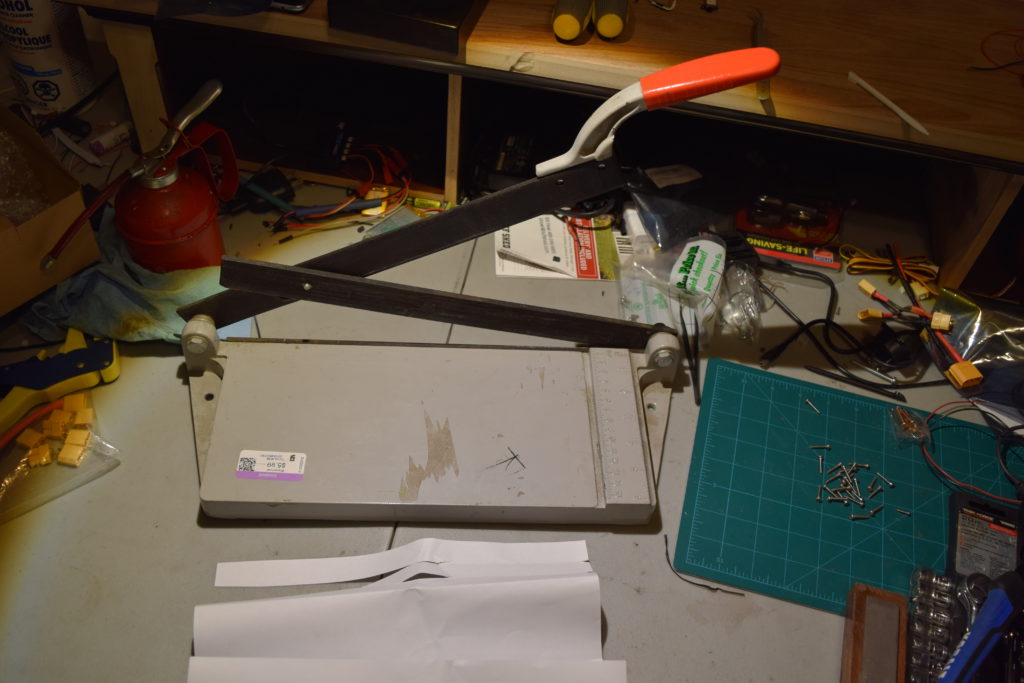

My wife needed help cutting a bunch of paper in half for a class she was helping run. I decided to be the hero husband and save the day with my paper cutting machine I had found at a thrift store a few months back. After the boasts about my great find from the thrift store and how awesome it was, I quickly realized it failed to cut more than half a sheet of paper. It worked great for me on sheet metal for making a license plate mount on a motorcycle. That might also be why it didn’t cut paper anymore. Regardless of whether it was bad at cutting paper when I got it or after I used it on sheet metal, it still wasn’t getting the job done. Below are some test cuts I attempted.

My first thought was that the blade was dull and needed to be sharpened. After 15 minutes with a 600 grit diamond block it looked nicer, but still failed to cut the second half of the paper.

Then it hit me, whats the point of having a bench grinder if not for potentially destroying the cutting edges on tools? Luckily it actually sharpened the cutting edge and I did not accidentally take a large chunk of metal out. Getting a nice edge with no more blunted sections took all of a minute on the grinder. That minute includes the time it took to spin up to speed. It was not a perfectly consistent angle, but the entire edge was now sharp. The proper way to do it would have involved making a jig to hold the blade at the correct angle to the grinder. I did it by hand with a little hope. It turned out good enough for what I needed.

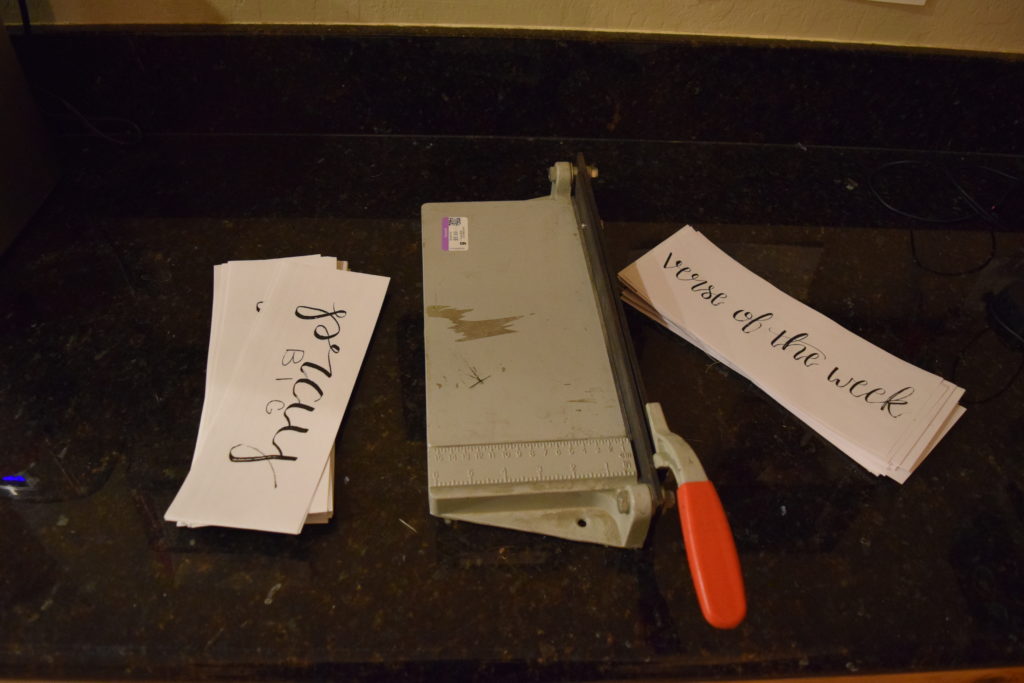

It finally cut the paper in half!

I thought I had finally done it, I had mastered the paper cutter. I was wrong, as soon as I tried it on the papers my wife needed cut it did the same half cut again. I then decided to turn my attention to the bottom piece. I removed it and cleaned up the edge using the 600 grit diamond block.

Still no dice… After taking the thing apart and putting it back together for the 4th time, I figured why not try the one bolt I haven’t taken off. I knew all of the cutting surfaces were good to go, the mating surfaces between the two cutting pieces was clean and smooth, and there were no other moving parts to look into. While cutting previously I had tried pushing on the handle towards the base to keep the cutting edges as close as possible during the cut, but this made no difference. I tightened the bolt at the rear of the device and lo and behold…

I had to tighten the nut way past what I thought would have been needed to keep it from unscrewing every time the handle was pushed down. But after tightening the nut it was cutting through paper like a hot knife through butter. After that hour of messing around I was able to cut the stack of paper in a minute or two.