ZL1 Axle and Tire Repair

As so eloquently stated, the car needs fixed. How the front axle and wheels were removed from the vehicle and subsequently went missing, the world may never know. The one year old who did it is now two and he still isn’t offering up an explanation. Of course before I started recording the video he was going on and on about how it was broken, wheels were gone, and daddy fix it. As soon as the video starts its pulling teeth to get him to repeat what he had been saying on his own.

I had recently purchased some small steel lathe stock so I started there for finding an axle. One of the pieces fit and just needed to be cut to length.

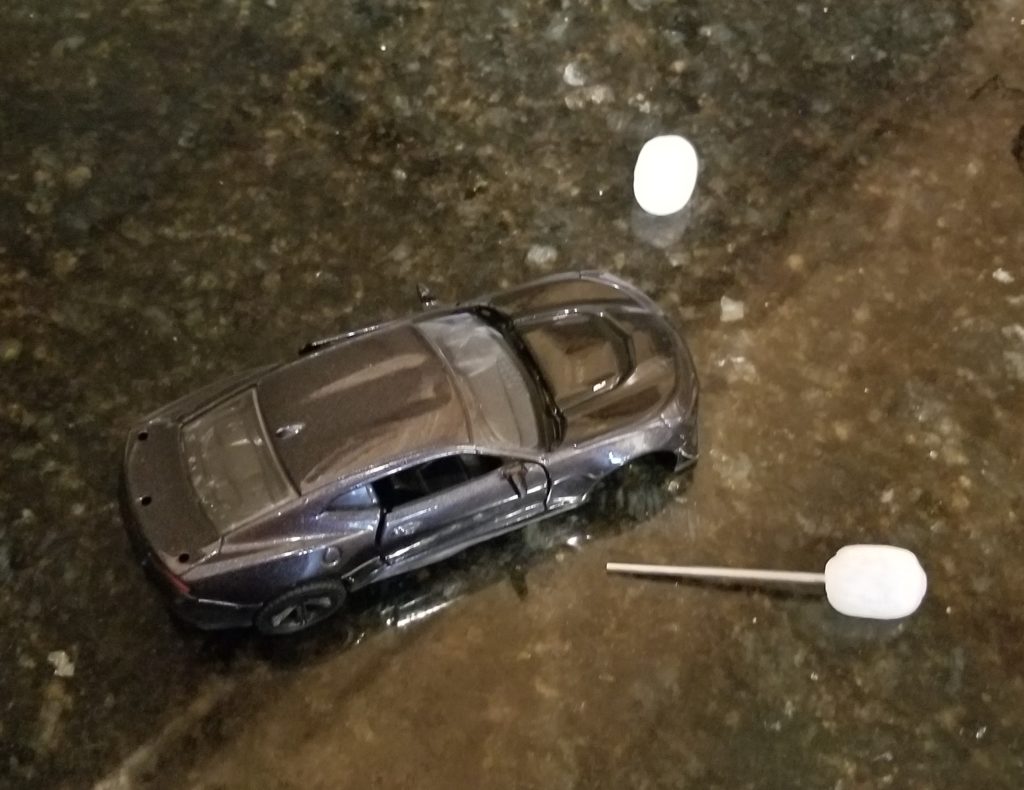

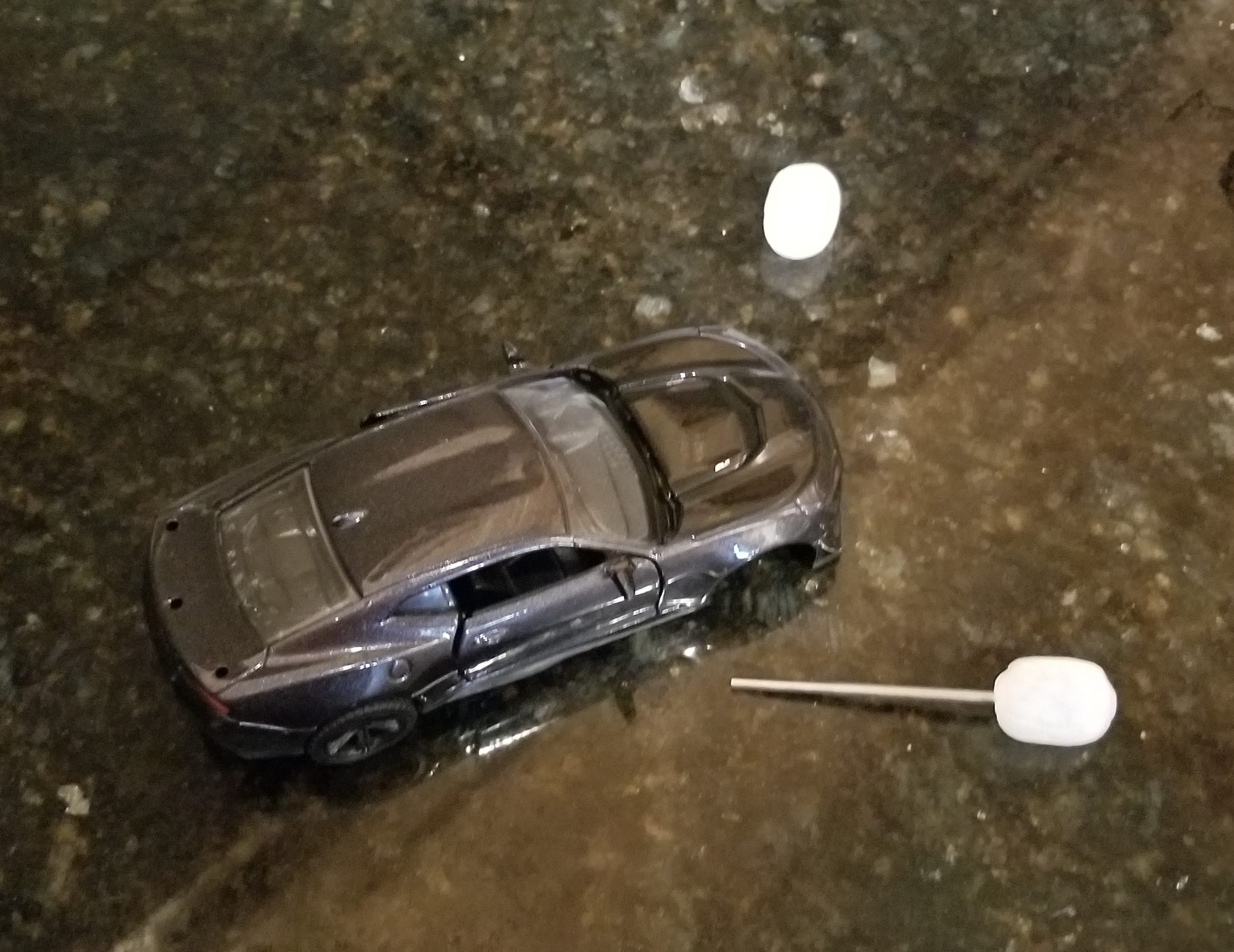

My first idea was to use some ThermoMorph I had seen in a video years ago and purchased because I thought it was cool. It was also something that was safe to use around a two year old who was yelling “FIX IT” the whole time. At least safer than metal shavings everywhere and letting a two year old wander around the garage with many sharp and dangerous tools. ThermoMorph is a thermoplastic with a relatively low melting point. Thermoplastics can be re-melted, thermoset plastics cannot. To melt it I boiled water and then let it cool down to ~150° F (60° C). Added the beads and waited for them to clump together and turn clear. I then removed the clump from the water with tongs and waited until it is cool enough to touch without burning my fingers.

I attempted to mold the plastic onto wheels, but the plastic would not stay on the axle. Even if I tried roughing up the axle ends to give the plastic something to hold onto it wouldn’t have worked. The plastic shrank away from the axle as it cooled. If I really wanted to use the plastic I would have had to make a mold to apply pressure while the plastic cooled.

All of the above took place one morning before I had to head in to work. The vehicle was not fixed, the toddler was not happy, and I had to go to work. I promised him I would fix it when I got home for work and it would be ready to go when he woke up the next day. He didn’t really understand, but being a toddler he was easily distracted and quickly forgot about our science project.

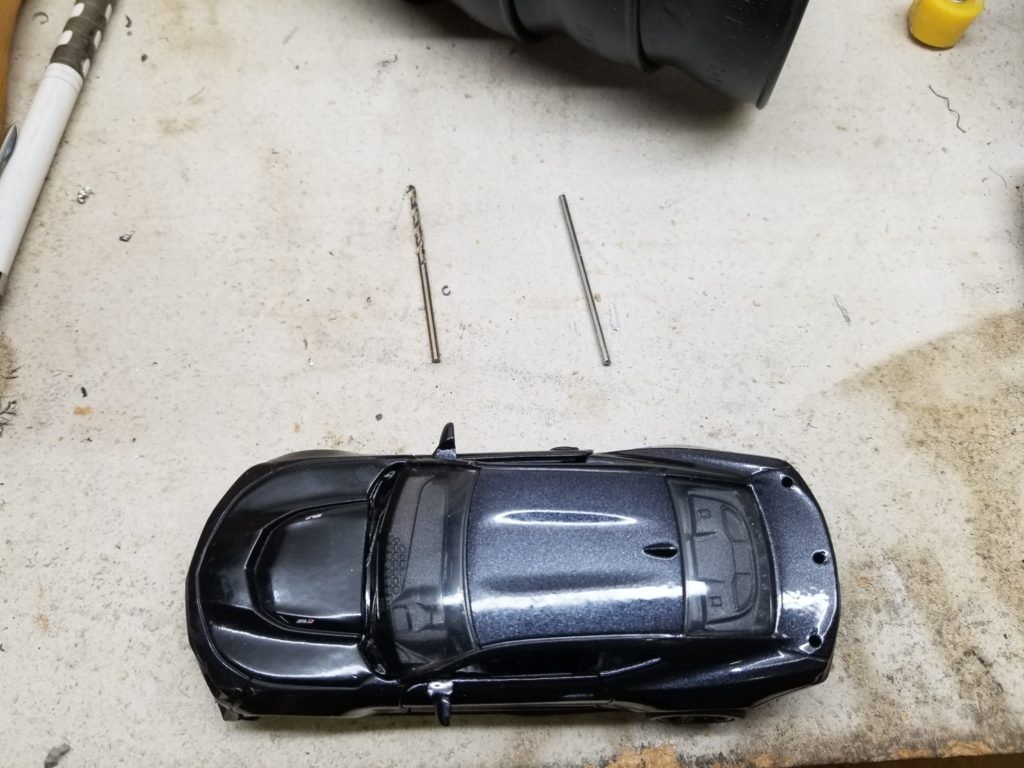

Plan B was make the wheels out of aluminum stock on the lathe. I started with 3/4″ stock. My stock was too long to fit in the lathe, so I used the plasma cutter because cutting things with electricity and plasma is fun. It is also way faster than the death wheel.

This was technically at the limit of what the plasma cutter could do at 3/4″ severance cut. It had no issues getting through the bar. It really only had a very small section of the cut that was 3/4″, so this isn’t a confirmation it can do 3/4″ plate. But I am happy with its performance nonetheless. The cut itself was only a couple seconds, setting it up took way longer.

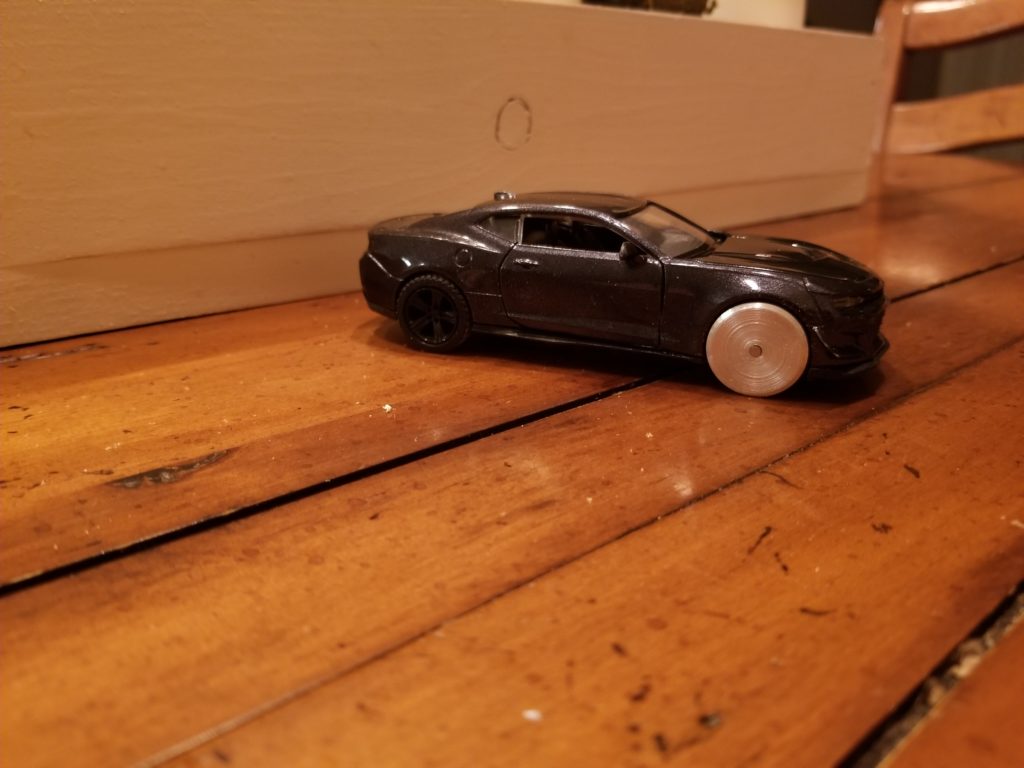

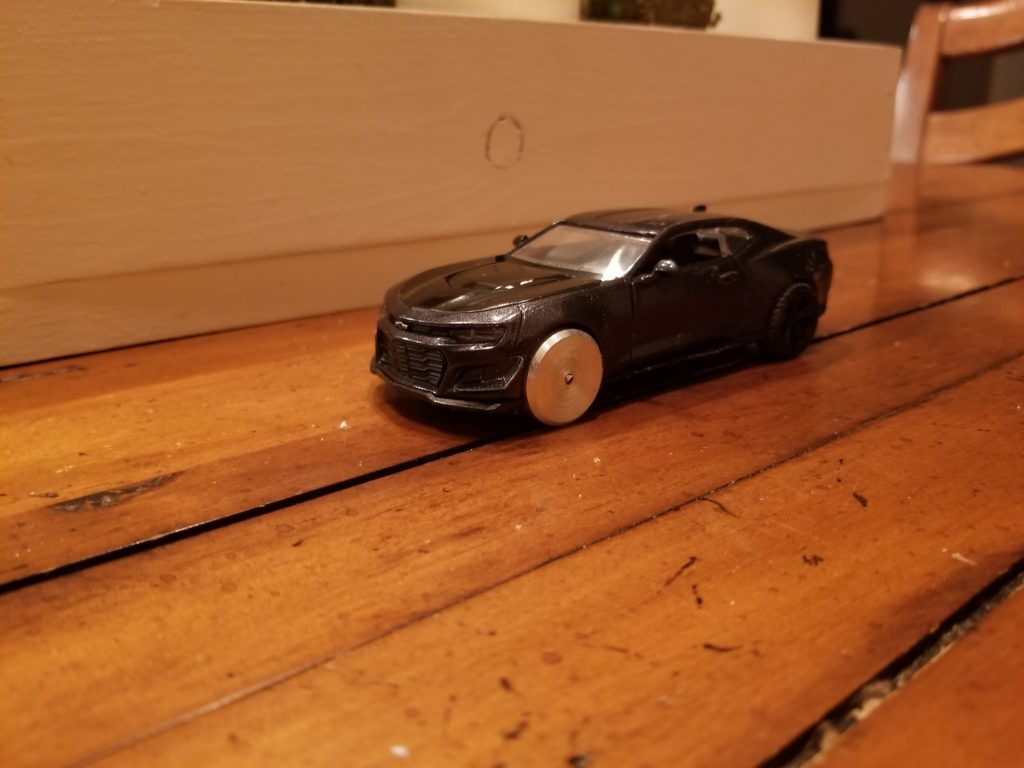

This is the part where I should put together a video of the machining. I might get around to it…hopefully. In case I don’t get around to it in a timely manner. I faced off the rough cut from the plasma cutter, turned down the stock to size, center drilled the end, drilled out a whole for the axle to fit in, started parting off the width of one wheel (20% of the way into the part), chamfered both edges of the wheel, and then finished parting off the wheel. After verifying that the first wheel fit and worked with the axle I did the same 20% parting, chamfering, and final parting.

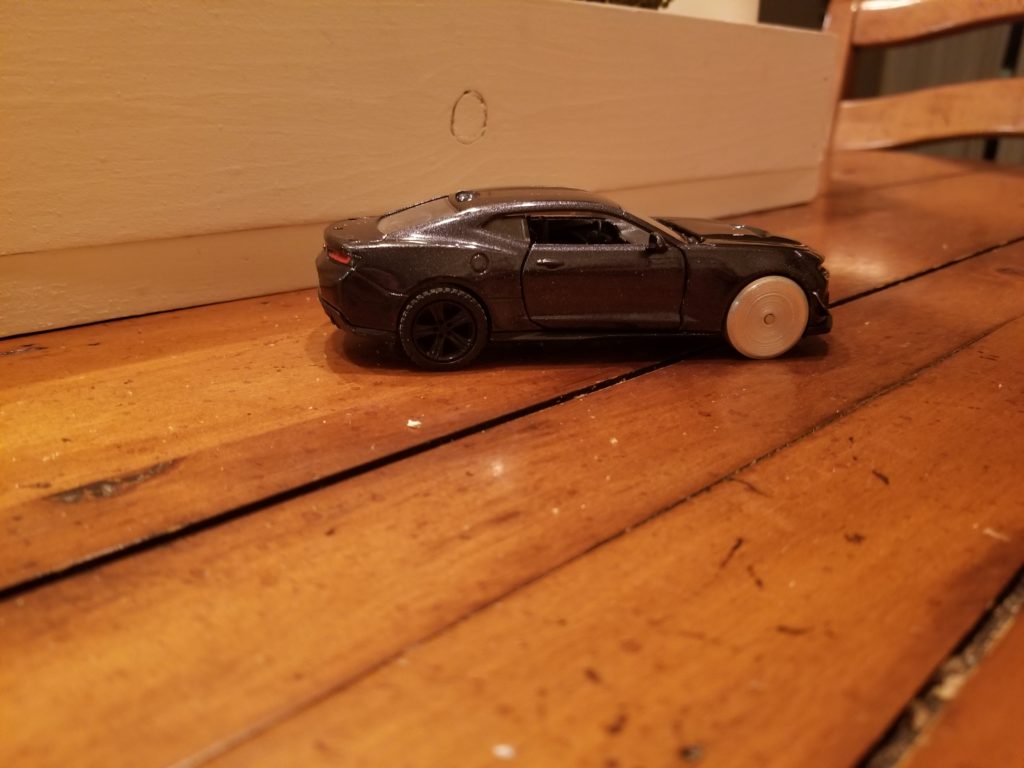

After machining the wheels I used blue thread lock to hold them onto the axle. I had originally intended to use a friction fit, but I drilled too large of a hole in the wheels for that.

The two year old seemed to approve of the final result. Hopefully these new wheels last a bit longer than the last ones.